Building knowledge of which tool is used for stamping?

Are you engaged with the manufacturing industry or company?

If so, then I’m pretty sure that you are aware of one of the most important processes associated with manufacturing. I am hereby discussing stamping. There are several manufacturing companies spread all over the globe which perform stamping activities for delivering components to other markets and industries like medical, automotive, aerospace, and others.

So, in this read, we will be understanding which tool is used for stamping. Along with this, we will also try to build an understanding of the term “Stamping”.

A look at which tool is used for stamping

Stamping also known as “Pressing” is a method of giving shape or molding flat metal sheets into the desired shape. The process is complex and involves a thread of small processes. However, the process is considered cost-effective to meet a large number of manufacturing needs.

Moving ahead to the stamping tools, the most common tools used in the stamping process is as follows:

Die: It refers to the tools used in manufacturing to give the shape to the material. The material is given shape by cutting it down through a specialized tool. This is the primary function that takes place in the stamping process.

Punching: It is a process of making a hole in the workpiece by applying force through a tool known as a “Punch”. In this process, scrap material is removed from the workpiece leaving a hole behind in the workpiece, as it enters the die.

Blanking Die: Another tool used in the stamping process is blanking. Here the workpiece is separated from the primary metal strip or sheet when it is punched. It helps in cutting down the waste material of the manufacturing firms, hence making the process cost-effective.

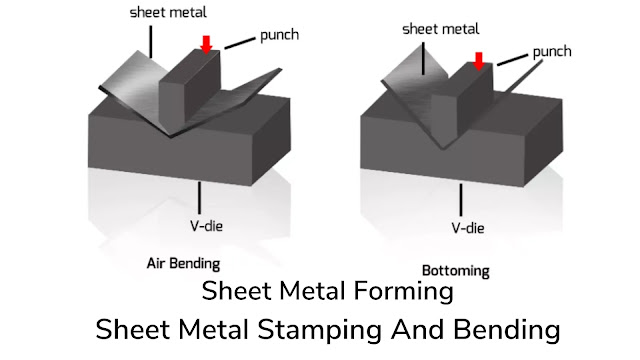

Bending Die: As the name reflects, it is the process wherein the material is given a particular shape. It is a general technique of giving an L, U, or V-shape to the metal. A plastic deformation takes place which stresses above the yield point but below the tensile strength.

Stamping press: The stamping press is the machine used to apply the force and pressure required for stamping. It is a heavy-duty machine that is designed to withstand the high pressure and force required for stamping. The press consists of a frame, a hydraulic system, a die, and a punch. The hydraulic system provides the force required to apply pressure to the die, resulting in the desired shape or design.

To Conclude

In conclusion, stamping is a process that requires specific tools to achieve the desired result. The die, punch, stamping press, blanking die, and bending die are the primary tools used in stamping. These tools are made of hardened steel and are designed to withstand the high pressure and force required for stamping. So, if you're planning to use stamping in your manufacturing process, it's important to know which tool is used for stamping to achieve the desired result.

Comments

Post a Comment